|

huagong laser Sapphire the whole industry chain provides optimal solutions Source:http://www.hglaser.com/news/22799_for_gongsixinwen_text.htmDatetime:2014-12-16 Brief:for nearly two years, sapphire glass market is growing. Sapphire glass has been looking forward to, the biggest advantage is its strong abrasion resistance, without fear or favour the scraping of metal, grit, its thermal conductivity is more excellent than plastic, glass and other materials, if used in mobile phones, cameras, watches and other industries, can significantly improve the scratch resistance of the screen scratch resistance. what is a Sapphire what we call the Sapphire and the multiplicity of corundum, mainly composed of alumina, used as a functional material with excellent, high temperature resistance, good thermal conductivity, high hardness, good insulation, good chemical stability and infrared characteristics, mainly for the LED with the mobile phones industry. cameo glass facing bottlenecks the last two years, sapphire glass market is growing. the sapphire glass, have been looking forward to, the biggest advantage is its strong abrasion resistance, without fear or favour the scraping of metal, grit, its thermal conductivity is more excellent than plastic, glass and other materials, if used in mobile phones, cameras, watches and other industries, can significantly improve the scratch resistance of the screen scratch resistance.

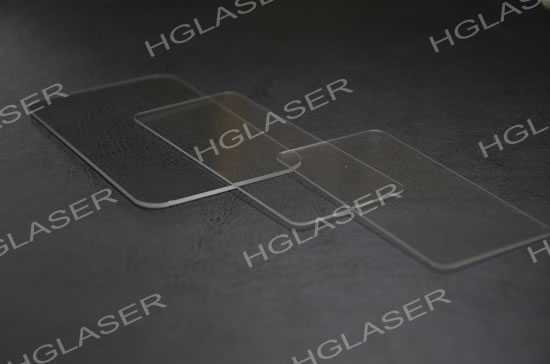

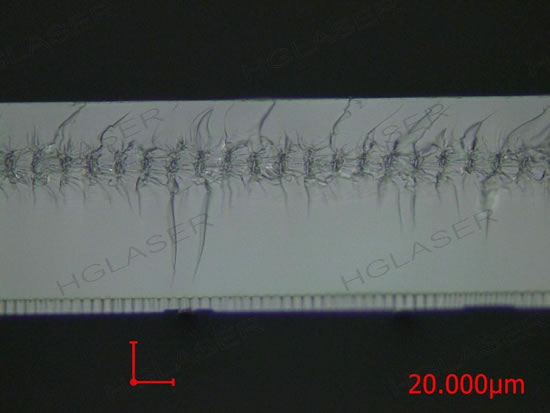

sapphire glass, laser cutting cell phone screen samples according to industry people said that sapphire glass processing technology is extremely complex. with the mobile phone industry, for example, made with sapphire-glass cell phone screen, just in the process of cutting edge can easily chipping lead screens and set aside. from material selection, cutting, grinding, polishing, each process may go wrong, in the eyes of producers, this process is a great challenge. at present, the domestic manufacturers, in order to break through the bottleneck, most urgently need to do is to introduce a new processing technology, sapphire glass, improve processing quality and processing efficiency.

Chinese laborers brought revolutionary breakthrough laser processing for Sapphire lasers since the 20th century, following the Atomic Energy, computer, semiconductor, another major invention of humans, known as "the fastest knife", "ruler", "bright light". using fine machining of Sapphire laser technology, its advantages are obvious:non-contact process, without supplies; processing speed is several times that of traditional processing methods; good stability, processing and high yield rate; one-time investment, reduce the overall cost. huagong laser as the world's authoritative provider of industrial laser solutions, always walk in the forefront of the market, for the first time to provide users with the most advanced and the most comprehensive laser processing solutions. huagong laser laser machining of Sapphire, has developed a series of ultra-fast precision laser processing equipment, bring new choices to the Sapphire the entire value chain. recommended equipment LED Sapphire automatic Super fast laser cutting machine

LED Sapphire automatic ultrafast laser cutting machine  LED chip side Zoom effect of the import of machines equipped with ultrafast lasers, laser focus system is used, beam quality, stability, and good cutting result, matching optical the marble terrace, high speed and high precision linear motor, processing speed, high production yield, and has a fully automatic loading and unloading systems, significantly increased production efficiency, LED automatic machining of Sapphire ultra fast cutting station.

recommended equipment Sapphire filament ultrafast laser cutting machine Sapphire filament ultrafast laser cutting machine Sapphire filament laser cutting sample imports the machine is equipped with ultrafast lasers, Sapphire cutting, combined with years of experience in designing exclusive laser focusing system, smooth cut edge, custom fixture design guarantees production, non-contact processing, high precision, without having to replace consumables, for filament support LED Sapphire cut.

recommended equipment Sapphire ultrafast laser precision cutting machine Sapphire ultrafast laser precision cutting machine laser cutting lens cover samples the machine equipped with imports Super fast laser, processing precision high, hot effects regional small, processing edge no Burr and residue, has automatically on bit function, equipped with exclusive cutting software, can on variety material for arbitrary shape of precision drilling, and cutting and the designated slot, micro processing processing, used non-contact type processing, processing speed is traditional tool of 10 times times above, Sapphire HOME key, are ideal for cell phones, camera protection glass the film cutting.undefined。3 |

| About Cardofcom|Add to Favorites|Register Cardofcom.net|Proposed Feedback|Contact us |

| Cardofcom.net---Card of com at net |

| 版权所有 沧州双一商贸有限公司 冀ICP备16002221号 |